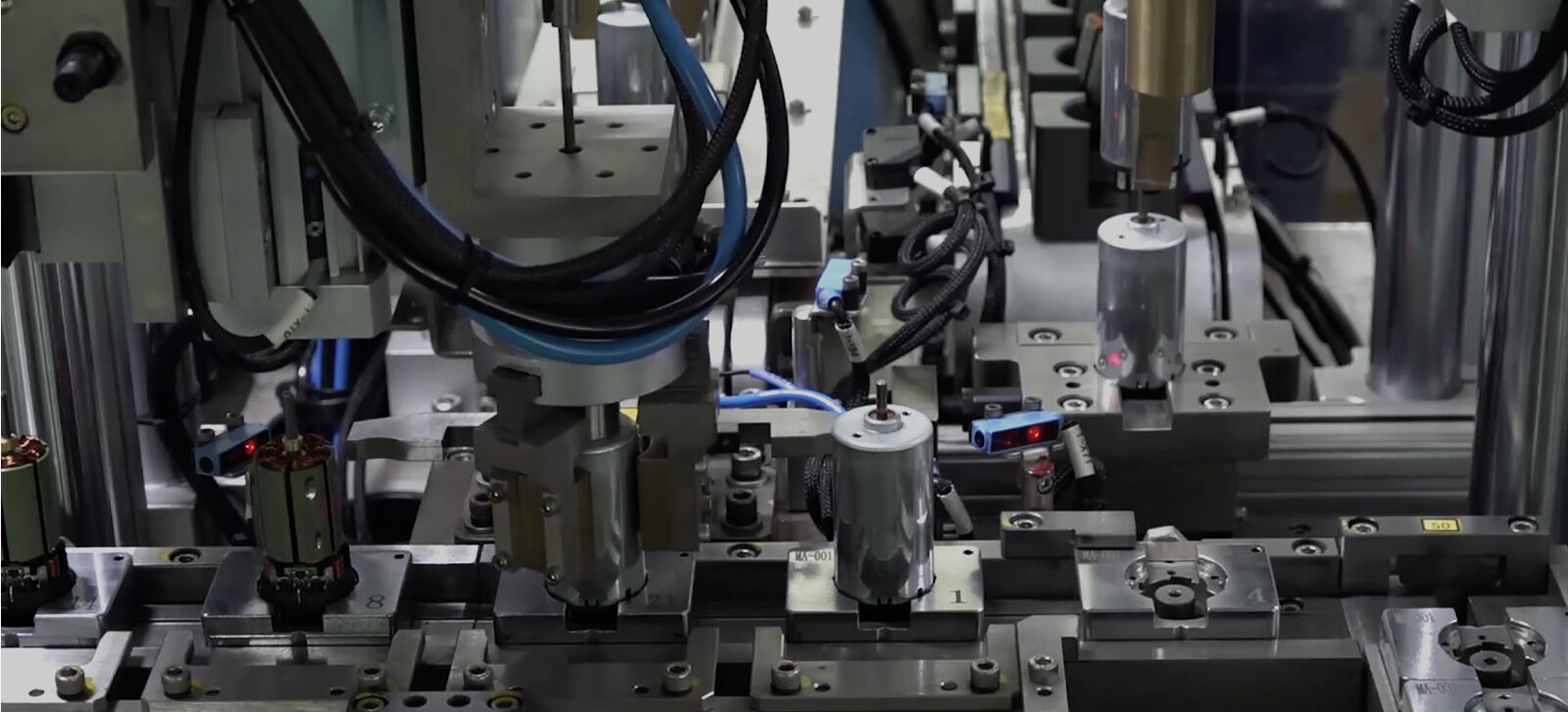

Staffing 0 people, beat 10 seconds \ pieces, finished rotor

Equipment composition: rotor loading - into commutator - winding - spot welding - secondary press fitting and wire wrapping shaping - fine turning - balancing - circular runout test - performance test and marking - dismounting

Intelligent, unmanned production and processing, support intelligent storage system to achieve efficient operation

Real-time grasp of on-site production, equipment operation status, convenient to coordinate the development of production plans