Staffing 1 person, beat 12 seconds \ pieces, finished stator

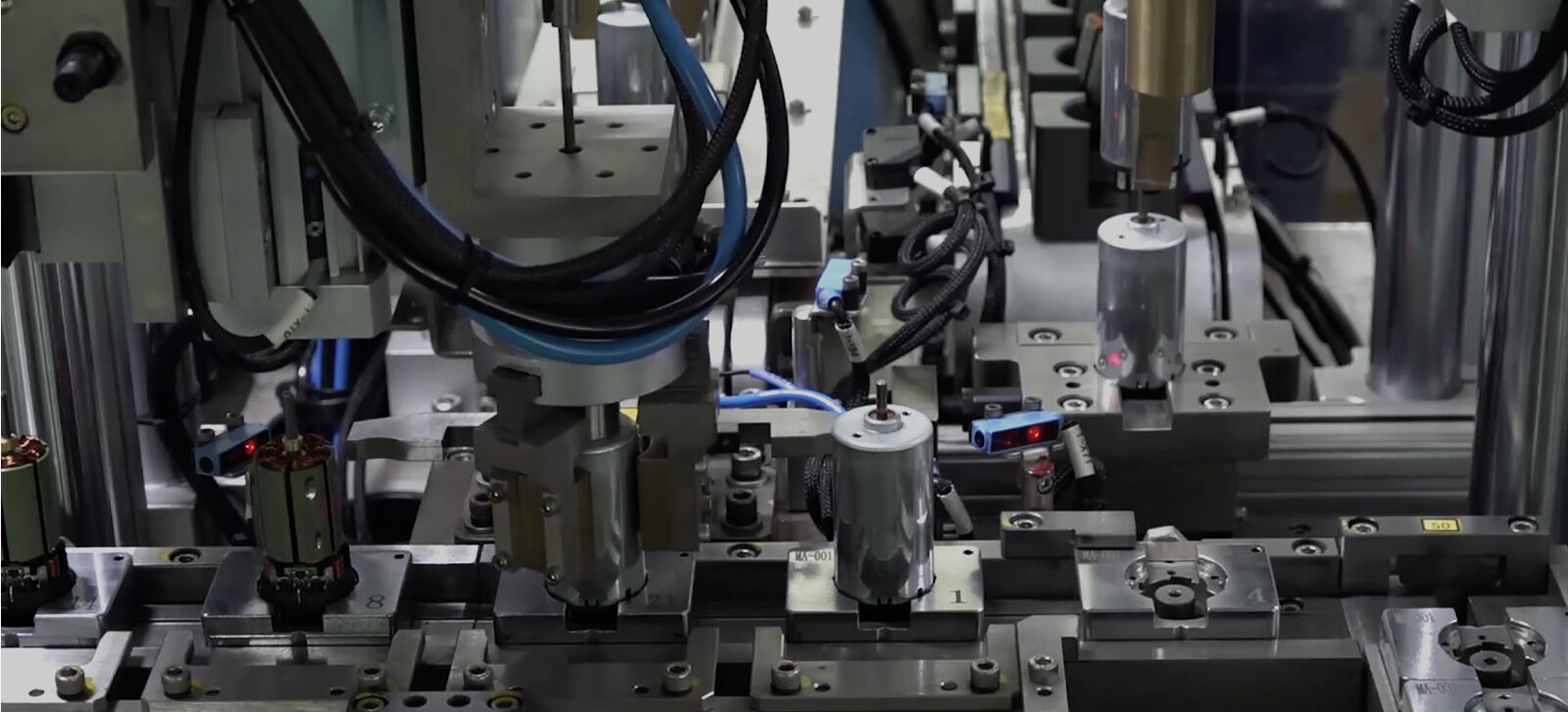

Equipment composition: paper insertion machine - into the end plate machine - high-speed stator winding machine - hanging wire machine - insert terminal machine - test marking machine - loading and unloading machine (core loading, finished product receiving box)

Combination of winding and wire management, breaking the long-standing bottleneck of automation implementation in the industry.

Highly intelligent identification function, not to miss the workpiece, to eliminate the inflow of defective products into the next process