If you are interested in our products , please contact our team.

1.1 Drive motor is an important link in the new energy industry, and permanent magnet synchronous motor has dominated

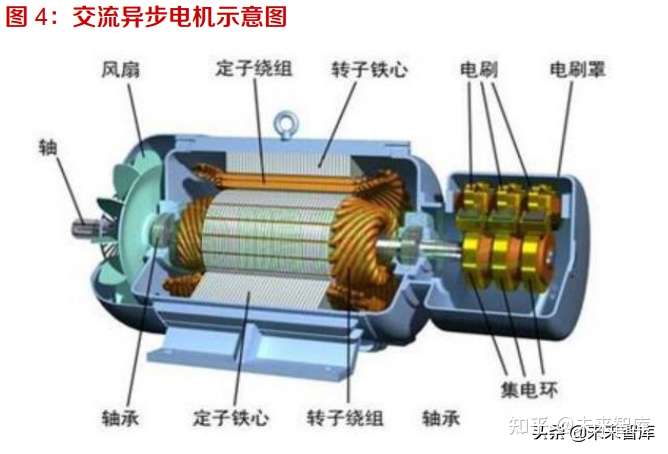

Drive motor is an important link in the new energy vehicle industry chain. The drive motor and its control system are one of the core components (battery, motor and electric control) of new energy vehicles, whose drive characteristics directly determine the main performance indicators such as hill climbing, acceleration and speed of the vehicle, and are important components of electric vehicles. Take the mainstream permanent magnet synchronous motor as an example, the motor is mainly composed of stator, rotor and mechanical structure, and the key components are stator and rotor.

Permanent magnet synchronous motors and AC asynchronous motors have become the mainstream choice in the passenger car segment. The permanent magnet of a permanent magnet synchronous motor means that permanent magnets are added to the rotor of the motor to further improve the performance of the motor, which is the difference between a permanent magnet synchronous motor and an AC asynchronous motor. This is the difference between a permanent magnet synchronous motor and an AC asynchronous motor. By synchronous, we mean that the rotor speed in the motor is always the same as the current frequency of the stator winding. In an AC asynchronous motor, the rotor is always "catching up" with the stator's rotating magnetic field, and in order to cut the magnetic induction lines and produce the induced current, the rotor speed is always slower than the stator's rotating magnetic field, which results in asynchronous operation, i.e., an asynchronous induction motor.

Both permanent magnet synchronous motors and AC asynchronous motors have their own characteristics. The permanent magnet synchronous motor itself has the advantages of torque density, power density, high efficiency, good speed control performance, plus its own small size, light weight and other advantages, but it is not without disadvantages, in addition to the cost of raw materials, it will have the problem of magnetic decay at high temperatures, which is why small and medium-sized pure electric vehicles can not be a long time high speed cruise. In contrast, the AC asynchronous motor has the advantages of simple structure, high reliability, better high-speed performance and acceleration performance; this is also the problem that some electric sports cars and medium and large SUVs that boast performance will prefer it, such as Tesla model S, model X, Azera ES8, etc. are using. But relatively speaking its disadvantages are reflected in the torque density, power density, efficiency density is low, and also accompanied by large size, heavy weight, heat generation problems. Overall, it can be understood that the electric car with permanent magnet synchronous motor has better range and the electric car with AC induction motor has better acceleration performance.

The share of permanent magnet synchronous motor in the domestic drive motor market is nearly 95%. Due to the advantages of China's rare earth resources and the characteristics of permanent magnet synchronous motor such as high power density, high peak efficiency, small size, light weight, diversified structure and wide range of applications, the installed capacity of permanent magnet synchronous motor in the country is rapidly increasing, and the installed capacity of domestic permanent magnet synchronous motor reached 2.69 million units in November 2021, with an installed capacity of 94%, occupying a dominant position in the new energy drive motor market. dominant position in the new energy drive motor market.

1.2 Flat-wire winding motor has obvious advantages and great potential for technology improvement

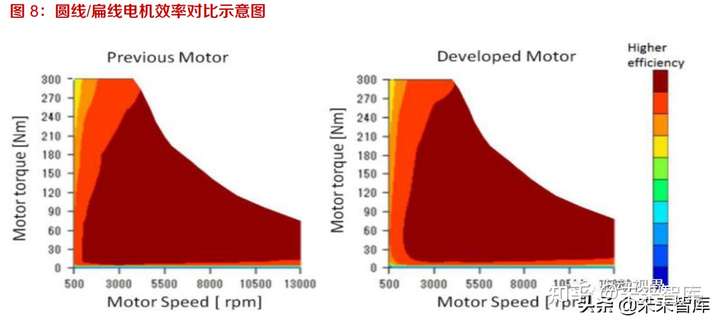

We judge that one of the technical trends of drive motors is the flat-wire winding (Hair-pin motor). The overall goal of motors is to improve efficiency and power density, and reduce size and weight. The distinctive feature of a flat-wire winding motor is the use of flat copper wire in the stator winding, which is first shaped like a hairpin, threaded into the stator slot, and then the end of the hairpin is soldered on the other end. By applying flat copper wire with larger cross-sectional area, the full rate of the motor slot is increased, which has the advantages of high power/torque density, high efficiency and better heat dissipation, etc. At the same time, it is easier to realize automatic production and meet the requirements of high product consistency after the explosion of the new energy passenger car market. But at the same time, flat wire motors need to overcome some shortcomings in large-scale applications, such as low yield rate, speed, standardization difficulties and patent barriers.

Flat wire has a high slot fill rate, high energy conversion efficiency brings battery cost savings. The power of the motor is positively correlated with the copper content, and a 20-30% increase in copper wire filling for the same volume means that the output conversion power is expected to increase by 20-30%. Flat wire motors have a high slot fill rate, with a pure copper slot fill rate of 70%, compared to about 40% for traditional round wire; 65% of the energy loss of the motor comes from copper consumption, as flat wire motors require shorter copper wires than round wire motors of the same power, lower winding resistance and lower copper consumption, resulting in higher conversion efficiency. In addition, the efficiency of flat-wire motors is 10% higher than round-wire in congested urban conditions (low speed and high torque). The high slot fill rate brings high efficiency area, and the WLTP range of vehicle road test is increased, and the battery capacity is reduced with the same range, which can effectively reduce the overall vehicle cost by 15%.

Flat wire has good heat dissipation and improves high temperature dynamics. Flat wire has better heat conduction and heat dissipation coefficient due to close conductor contact and reduced slot voids, and the thermal conductivity between windings is 1.5 times higher with high slot fill rate than with low slot fill rate; the AC resistance decreases at low and medium speeds, and the stator temperature rise is reduced by 18% compared with round wire, and the thermal resistance in the slot is reduced, resulting in better heat conduction. The temperature rise can be reduced by about 8~12%, and the vehicle can achieve better acceleration performance under the condition of lower temperature rise.

The power density of flat wire motor is higher, and the vehicle is more powerful. Flat-wire motors with high slot fill rate and higher torque density, reduced effective volume, increased torque and higher power, increased power density (for example, SAIC's second-generation EDU high-power Hair-pin motor increases power density by 20%), and enhanced motor torque output capability, further improving power density and overall vehicle power performance. The power density of round-wire motor is about 3.5kw/kg, which can no longer meet the requirement of 4.0kw/kg in the 13th Five-Year Plan, while the current power density of flat-wire motor of leading enterprises is about 5kw/kg, so flat-wire motor is the inevitable trend of future development. In addition, the flat wire motor takes advantage of its large end conductor gap, cooling oil can directly penetrate into the end of the winding to absorb the heat of each conductor, reducing the motor winding temperature by more than 68%, which greatly improves the power density and torque density level of the motor.

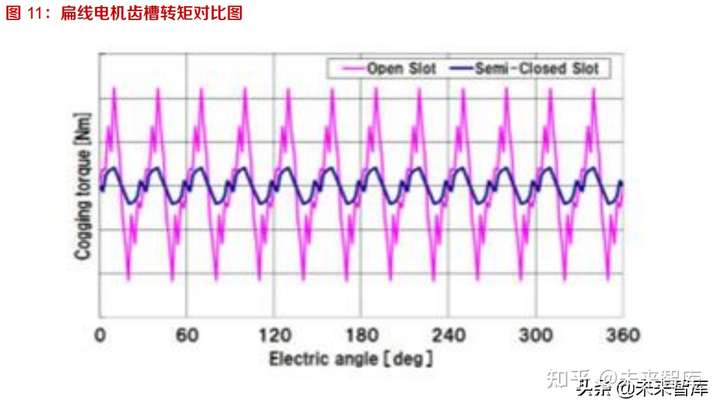

Flat wire motors have low electromagnetic noise, making the whole vehicle quieter. Flat-wire motors have higher wire stress and winding rigidity, better armature stiffness, higher elastic modulus, and changes in object modality, which are more conducive to impedance resonance and suppression of armature noise. In addition, cogging torque is an inherent problem in permanent magnet motors, and although it does not increase or decrease the average effective motor torque, it causes speed fluctuations, motor vibration and noise (NVH). The flat-wire winding is inserted through the end of the core, eliminating the need for wire insertion through the slot, and the relatively small slot size in the electromagnetic design reduces motor cogging torque by 19% and NVH by 12%, further suppressing electromagnetic noise.

The small size of flat wire brings high integration efficiency and meets the development trend of all-in-one electric drive. Compared with traditional round wire and copper wire winding, the effective volume of flat wire core can be reduced by 15% in axial direction, 10% in outer diameter, 20% in copper usage and 10% in overall weight, which is in line with the current trend of light weight and miniaturization of motors. trend.

1.3 mainstream car companies have changed the flat wire motor, flat wire motor penetration rate will rapidly increase

Among the top 15 new energy vehicle sales in 2020, only some models such as Ola R1, Ideal ONE, and Weilai ES6 use flat-wire motors, and the penetration rate of flat-wire motors in 2020 is less than 10%, and with a 5.4% penetration rate of new energy vehicles, the overall penetration rate of flat-wire is less than 1%.

In 2021, the penetration rate of flat-wire motors will increase rapidly. 2021, Tesla and GAC will change to flat-wire motors, BYD DMI will adopt flat-wire motors, and SAIC and Great Wall will switch to flat-wire motors in their new models. 16 models with flat-wire windings were among the top 40 models sold in the first November of 2021. We estimate that the flat-wire penetration rate of the top 40 models reached 31.1%, and since the top 40 models in November accounted for 76.6% of total passenger car sales in that month, the current flat-wire motor penetration rate is expected to exceed 23.9%. (The penetration rate of flat-wire is higher for high-end models with lower sales volume)

Considering the advantages of high power density, high energy conversion efficiency and good heat dissipation of flat-wire motors, the penetration rate of flat-wire motors is expected to increase rapidly in the next 3-5 years.

1.4 dual-motor configuration to enhance the global drive motor market is expected to reach 74 billion yuan in 2025

The performance of new energy vehicles is about to be upgraded, and the proportion of dual-motor arrangement is rising. Currently, mid- to high-end models are mostly equipped with single-motor versions and dual-motor versions. Single-drive motors are mostly found in low-end models, where pure electric vehicles have front or rear drive motors, and hybrid models generally have front drive motors; dual-drive motors are generally found in high-end models, where pure electric, plug-in hybrid and hybrid are involved, with one drive motor deployed in the front and one in the rear. The current penetration rate of new energy vehicles is rising rapidly, and as the recognition of electric vehicles in the consumer side increases, we believe that the trend of upgrading the performance of new energy vehicles will drive the demand for 4WD dual-motor and even triple-motor versions, and the market share of dual-motor models may further increase.

The new energy vehicle market has exploded, and the installed capacity of drive motors is growing rapidly. Thanks to the explosion of the domestic new energy vehicle market, the installed capacity of domestic new energy drive motors has achieved rapid growth in recent years, with domestic new energy vehicle sales exceeding 3.3 million units in 2021, assuming a 12% penetration rate of dual-motor models, the installed capacity of domestic drive motors is expected to reach about 3.7 million units in 2021, with a year-on-year growth rate of more than 150%.

Better new energy vehicle growth environment, the global new energy drive motor market size is expected to reach 74 billion yuan in 2025. In the medium and long term, driven by factors such as double points, carbon emissions and model advances, there is a stronger certainty of high growth in sales of new energy vehicles; in the long term, longer range will become the mainstream trend of new energy vehicles. It is expected that 9.25 million vehicles will be sold globally in 2022 and 5.3 million in China; 22 million vehicles will be sold globally in 2025 and 9.45 million in China; and the annual sales penetration rate of EVs will be close to 45% in 2030. In the medium and long term, EVs form a two-way feedback to fuel car substitution, with positive feedback from EVs, more mature support, and continuous improvement of using experience; negative feedback from fuel cars, contraction of support, and continuous decline of using experience, in this context, new energy vehicles are expected to accelerate the substitution of fuel cars. Along with the downstream demand, coupled with the future motor performance upgrades brought about by the dual-motor ratio, the future of new energy drive motor market is expected to usher in a golden growth period. (Report source: Future Intelligence)